As a top quality veneer vinyl flooring supplier, Sreelance Material Technology provide a wide range of Veneer SPC flooring product for flooring brands and flooring distributors across the world. Our V-SPC flooring range from 5mm up to 7mm thickness. Using top quality oak veneer from AB grade to ABCD mixed grade, most suitable for consumers that are looking for top notch luxurious waterproof flooring that has the true appearance and surface of wood flooring. Combining the wood with polymer stone core it has the benefit of both floorings. Waterproof and true luxurious.

How are Veneer Vinyl Flooring Made?

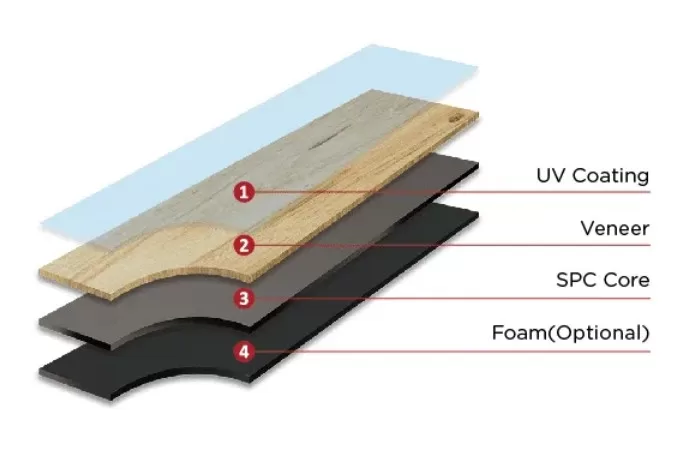

Wood veneer vinyl flooring is a hybrid structured resilient flooring product. It is made from in multilayer structure that has a wood veneer on the top, a rigid core SPC middle layer, and a EVA or IXPE as underlayer. As different materials are combined together to create this unique flooring product, the manufacturing process is done in discrete manufacturing process.

Structure of Wood Veneer Vinyl Flooring

Comparison between Hard wood, V-SPC, and Vinyl SPC Floorings

| Hard Wood Plank | V-SPC Plank | SPC Plank | |

|---|---|---|---|

| Compositions | Plywood or HDF core with wood veneer | Vinyl SPC core with wood veneer | Vinyl SPC core with PVC top wear layer |

| Dimensional Stability | Moderate depending on moisture rate | Equivalent to SPC as wood veneer compositions are specially treated | High dimensional stability performance rating |

| Water Resistance | Moderate to Low | Waterproof | Waterproof |

| Fire Resistance | Surface Treatment for Bfl-B2 rating | Bfl-B2 rating on Veneer | Bfl-B1 |

| Pest Resistance | Susceptible to pest | Pest-proof | Pest-proof |

| Environmental Safety | Sustainable wood, variable | Meet A+ air quality | Meet A+ air quality |

Manufacturing Process of Veneer Vinyl Flooring

As the manufacturing process of V-SPC is done in discrete manufacturing process, the production steps can be categories into three main steps, the making of wood veneer, the making of SPC core, and the combination of wood veneer with SPC core.

Wood Veneer Treatment Process

Veneer wood has to be treated to ensure moisture level is diminished and anti-pest treatments done for long lasting performance. The surface can be treated with different surface treans and lacquer for texture and color variances. This process is the same as to how engineering hardwoods are being made.

Rigid Core SPC Extrusion Process

Rigid core SPC sheets are being extruded using extrusion production line. The difference to standard SPC manufacturing is that with V-SPC, only to core base layer is extruded, and not laminated with print layer nor wear layer. Once the SPC core is extruded, it goes through 48 hours of acclimation to stabilize the sheets before adhesion with wood veneer.

Combination of Wood Veneer with SPC core

The manufacturing process to combine wood veneer layer and SPC core needed a cold press technique to adheres the two layers together. Once wood veneer is adhered to the SPC sheet, they will go though the cutting and slotting machine to get cut into the require dimensional sizes.

Key Factors that Defines the Quality of V-SPC Flooring

There are multiple factors that determines the quality of V-SPC floorings.

Raw Materials Aspects

- Grade of wood veneer

- Grade of SPC core performance

- Balancing layer

- Quality of glue

Manufacturing Processing

- Wood treatments

- SPC controlling and seasoning managements

- Laminating process control

- Slotting process

Sreelance is a Professional Supplier in Top Quality Veneer SPC flooring

Here at Sreelance, we provide the top quality product solution in veneer SPC floorings. Whether you are a flooring brand or flooring product wholesalers, we have got all customized V-SPC products available for you to import. Access to different types of woods, grades, thickness, and sizes, you will find everything you need with Sreelance.

Our V-SPC Product Specifications

Our some of the most common products available for V-SPC includes the following:

- VSPC 1220 x 152 x 5.0/0.6mm + micro bevel + brush + 5G Click

- VSPC 1220 x 152 x 7.0/1.2mm + micro bevel + brush + 5G Click

- VSPC 630 x 127 x 5.0/0.6mm + micro bevel + brush + 5G Click

- Other specifications can be made according to demand.