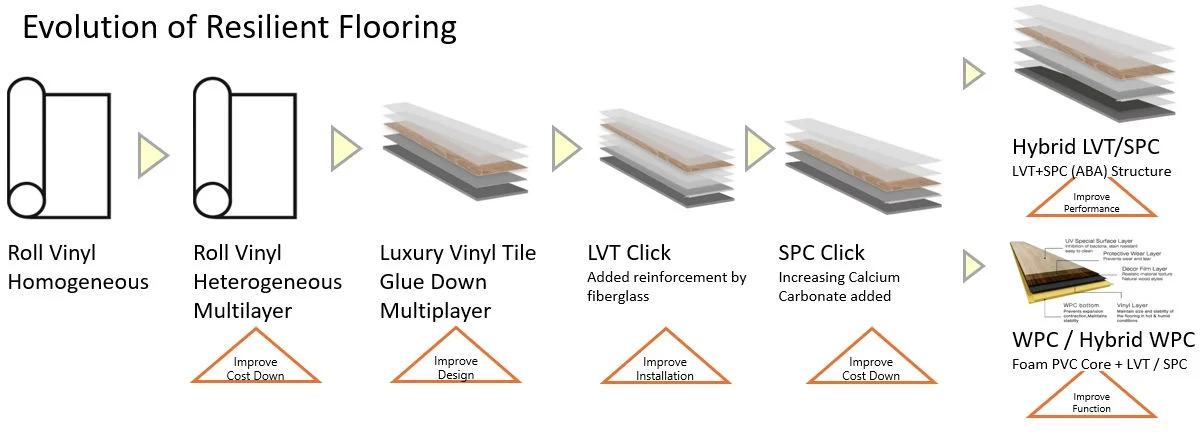

The evolution development for resilient flooring has went from commercial applications to residential applications distinctively as substantial number of design development has went to offer almost endless patterns and colors for the LVT category. The trend for LVT evolution has also sparked a wide range of product development directions, which NPD focus more then just cost down approach.

Much of the latest LVT product developments are more concerned in functionality and performance, suggesting that there are still fundamental niche that has not been fulfilled by existing LVT products. However, cost effective LVT and SPC product lines does contribute largely to the success of market sales and business development in the whole of floor covering industry.

Product Evolution in Resilient Flooring Category

| Time of Launch | Product | Distinctive Features when first Launched |

|---|---|---|

| 1938 | Roll Vinyl Homogeneous Flooring | Mass production for polymer based flooring |

| 1950 | Roll Vinyl Heterogeneous Flooring | Improve cost structure |

| 1980 | Glue Down Luxury Vinyl Tile | Improve aesthetic design |

| 2011 | Click Luxury Vinyl Vinyl Tile | Improve installation |

| 2017 | Click Rigid Core SPC Flooring | Improve rigidity and cost down |

| 2020 | Hybrid LVT / SPC Flooring | Improve dimensional stability performance |

| – | Hybrid WPC Flooring | Improve sound acoustic function |

What are the next trends in Resilient Flooring Product Developments?

The resilient flooring industry has underwent significant product developments and competition. With increasing market competitiveness, both resilient flooring brands and manufacturers alike are exploring for new generation of innovations. Some of the developments are generated from increasing environmental sustainability requirements while others also focus on performance towards niche flooring markets.

Here at Sreelance, we have outline some of the innovative solutions in resilient flooring products:

- Non PVC resilient flooring

- Zero Curling performance LVT

- Glue free loose lay LVT flooring

- IMO Compliant LVT flooring

Non PVC Resilient Flooring

With increasing concern over toxicity of PVC polymers in building materials, many NGO are ready launching campaigns against PVC related manufacturings. Leading flooring brands such as Mohawk Industries and Shaw Industries are also progressively working on Non PVC LVT and SPC products. There is no doubt that the next generation LVT and SPC product lines will be associated with PVC alternative floorings. Both polypropylene and PET polymers are currently on the race, both showing prominent progress by brands.

Zero Curling LVT

Standard luxury vinyl tiles with minimal Floorscore standards are simply not good enough. There has been considerably large complaints and product failures when LVT products are installed in conditions where there is distinctive temperature variance. As a result of LVT curling, builders and contractors need to completely remove the already glue downed LVT and reinstall new floorings. Cause penalty, additional material and labour costs. There is a need for failure proof zero curling LVT that can handle temperature fluctuation with product standards that well exceed the Floorscore standards.

Glue Free Loose Lay LVT

Glue is messy. Its always a hassle to apply the glues and worse having to remove it at product end of life. Flooring removal can be costly and once removed, the subfloor also needs a proper preparement for the next flooring renovation. With such problem, glue free loose lay LVT is considered a solution that could revolutionize the market. Innovative solutions such as IOBAC’s Tab-It is a way to install LVT flooring without having to apply glue.

IMO Compliant LVT

IMO certified flooring products are designed to be used in special environment such as for offshore platform, ships, and vessels. With an enclosed environments, IMO certified floor covering has a restrict standards on fire retardants. IMO compliant LVT flooring are designed to meet that niche.