When you purchase rigid core SPC planks from Asia, it is important to make sure that all your production orders are inspected for its performance and appearance. Here at Sreelance, we make sure all our production batches are inspected, recorded, and reported to our clients. This transparent reporting system allows us to build a better trust with our clients, providing exceptional service in international trading.

Rigid Core SPC Plank Inspection

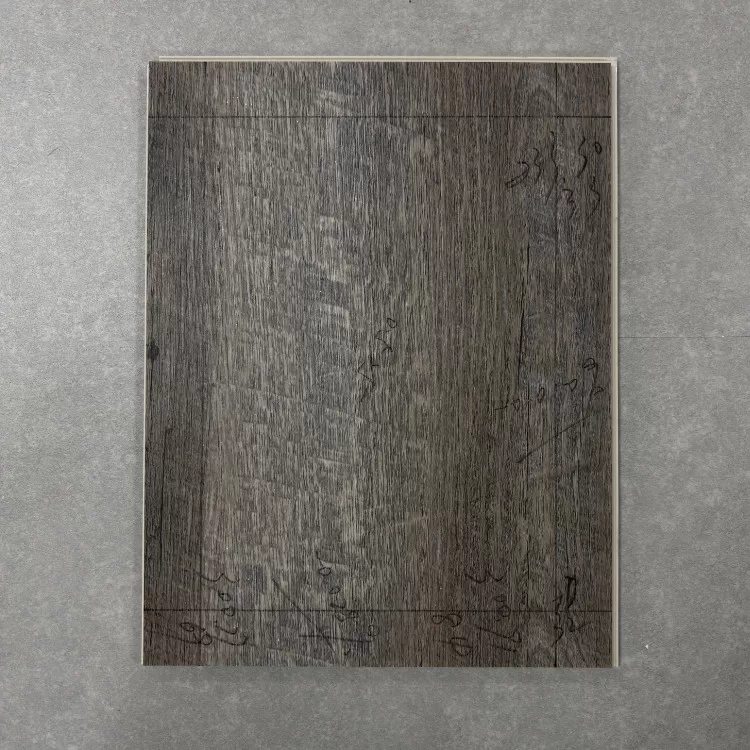

At end of each production batch, our quality team will carry out inspections on the finished goods. The above picture displays a SPC plank that has been tested for its dimensional stability and curling. after 6 hours of oven at 80°C, the plank is tested for dimensional change and curling gap.

Product Appearance Inspection

Before the finished products (SPC floorings) are being loaded for shipping, we will random inspect the goods based on appearance and basic functionality. Our inspection criteria for the appearance includes packaging, surface appearance, assembling, gloss level, dimensional lengths, and etc.

Set of Criteria for Appearances & Basic Functions

| Package / Box | Surface Appearance | Edge | Dimensional | Surface |

|---|---|---|---|---|

| Print Clarity | Embossing Texture | Bevel | Length | Flatness |

| Color & Color Variances | Print & Color Variation | Locking System | Width | Gloss Level |

| Marking/Tag Correctness | Surface Dent / Bubble | Gap | Thickness | |

| Box Tear | Surface Scratch | |||

| Other Damages | Other damages |

Importance of Transparent Reporting System on Product Inspection

For flooring importers there are a few aspects why you need a transparent reporting system on product inspections. The truth is, most of the international risks are associated with either fraud or low product quality. Trade fraud occurs when a supplier claim they produced something they didn’t, and low product quality risks when unacceptable defected products are being shipped and delivered. With international trade, once payments are made and products are received, product failure claims and warranty are extremely hard to deal with. Therefore establishing a transparent reporting system can help to solve and minimize these risks.

Core Reasons for Transparent Reporting System in Product Inspections

- Making sure product order are manufactured with correct product and quantity.

- Making sure only acceptable quality of goods are being shipped and delivered.

- Make sure the sourcing department has access to how products are inspected.

- Helps to Narrow Down Product Defect Responsibilities.

- Prevent Systematic Risks in Production Manufacturing and Improve Quality Consistency.