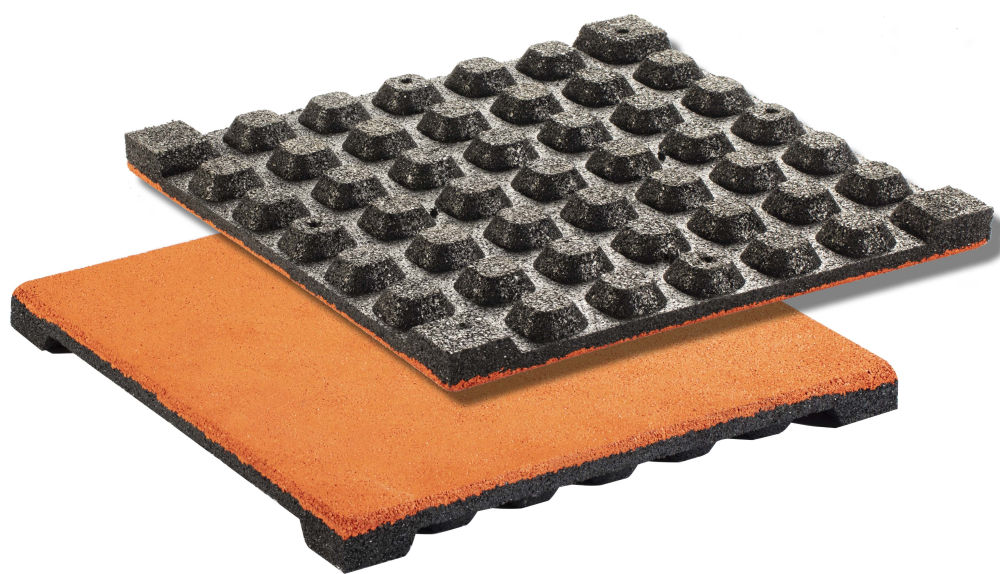

Recently we came across an interesting flooring product that has used polypropylene to modify its rubber composition. The intends of additive polypropylene is to reduce the green house gas emission as rubber generally has very high GHG emission. Generally 1 ton of rubber manufacturing can produce 13 to 21 tons of CO2, while production for polypropylene polymers only has 2 to 3.5 tons of CO2 emission. By increasing the ratio of polypropylene as fillers, this rubber based outdoor flooring will have reduced its total GHG emission while keeping most of its flexible and resilient mechanical properties.

Why Polypropylene is used for Outdoor Flooring?

Polypropylene is an excellent plastic for outdoor applications due to its high heat resistance that contribute to better dimensional stability and rigidity. Binary blend of polypropylene (PP) and rubber material is called a thermoplastic elastomer (TPE) which offer numerous advantages related to thermal properties and behavior, including good heat resistance, material stability across a wide temperature range, and ease of processing due to lower energy consumption and shorter production cycles. As outdoor flooring will have extend exposure to sunlights, facing high temperatures across different seasons of year, modified rubber with polypropylene (TPE) makes an excellent material for outdoor flooring manufacturing.