Recent US reciprocal tariffs against China has many impact for the flooring industry. Flooring brands and importers are seeking supply chain solutions to avoid the tariff risks and burdens. With increasing demands to shift product sourcing from China to other East Asia countries, manufacturers in China has try to undergo strategic supply chain practices to avoid losing product order from its customers. One common practice is to invest new production plant in South East Asia. Countries such as Vietnam, Thailand has seem large manufacturing expansion with investments coming from China.

However, there are also unethical supply chain practices which involves finished product goods to be shipping to a third country before delivering to United States market. The third country act as a step stone for the finished goods to be label as made in a third party country so it can avoid the tariffs otherwise. South Korea for example are facing this supply chain issue as many flooring manufacturers in China are using South Korea as a transfering platform to get their flooring products marked as Made in Korea.

To counter these ethical supply chain practices, many East Asia countries and South East Countries are working on countermeasure illegal flooring country-of-origin practices.

South Korea uncovers ‘Made in Korea’ breaches intended to avoid US tariffs

According to the latest report by The Straits Time and South China Morning Post, The Korea Customs Service (KCS) has already found increasing trend for US-bound shipments that attempts to disguise its country-of-origin. With increasing violations for these products, the KCS has launched a task force to crack down and prevent these illegal export attempts.

Vietnam’s Follow Up to Prevent country-of-origin Violations

Vietnam’s trade ministry has issued a directive plan to crack down on illegal transhipment of goods to the United States. With increasing tariff tensions between China and United States, transhipment of goods has been used as a method to avoid the reciprocal tariffs against made in China products.

As Vietnam has nearly 40% import reliance of goods from China, the US government has openly accused China of using the Southeast Asian nations as a transhipment hub to dodge US duties. The trade ministry, customs and other agencies of Vietnam are working on plans to strengthen supervision and inspections to ensure the country-of-origin are legitimately correct.

What are the Major Implications for Flooring Manufacturers in South East Asia?

With tighter policies against transhipment that are aimed to alter its country-of-origin, flooring manufactures will need to implement a more transparent supply chain management policies internally. The crack down on China made flooring that tried to avoid US tariff will reduce unfair competitiveness between Chinese flooring manufacturers and South East Asia flooring manufacturers. However, these manufacturers will also need to implement more ethical supply chain practices to avoid potential custom and logistic risks. The major implications and impacts are as following:

- Ethical sourcing of raw materials

- More transparent material managements

- Operation managements with tracking system

Ethical Souring of Raw Materials

Ethical material sourcing are becoming a more important aspect in manufacturing. When sourcing flooring products from China or Asia, it is necessary to know where your products’ raw materials are from. If the manufacturer or supplier you are working with cannot provide a clear evidence of where they source their materials, then as an importer you will have to be concerned.

There are a few different ways which can help you to determine where your manufacturer’s raw materials are from:

- Ask for purchase invoice, material delivery record, payment receipts / invoices

- Trade agreements and partnership agreement with raw material suppliers

- Certified proof of raw material origins

- Factory site audit to inspect materials

- Qualified third party inspection

More Transparent Material Management

To ensure best practices in supply chain managements and raw material managements, many leading brands are asking their suppliers to provide more transparent informational on material purchase, manufacturing, and material usage. Different corporate will have different ways to valid the information that is provided by the manufacturers, such as factory site inspections, power usage rate, invoice auditing, and etc. All these requirements requires the manufacturers to provide more transparent disclosure on supply chains, and helps the buyer to effective manage its vertical supply chains, including complying with flooring country-of-origin.

Operational Management with Tracking System

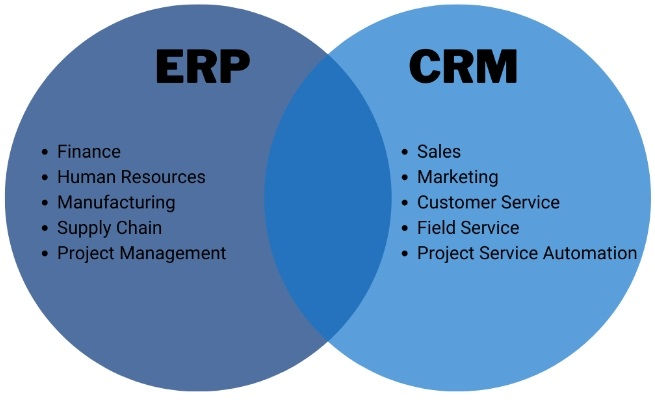

As ERP system are advanced, many corporate will ask manufacturers to implement ERP system that help the buyer to manage its information and data. It is a very common practice by higher level of industries or industries that has significant large production capacity. For the building material industry, supply chain ERP system are mostly used by companies what has tremendous large product management needs, whether for finished goods or components.