When it comes to manufacturing of resilient vinyl floorings, there are hundreds of suppliers and factories to choose from in Asia. It is a problem for many flooring importers as different suppliers and manufacturers actually has different level of experience and quality in their vinyl flooring products. With commercial vinyl floorings, this quality gap can further be a concern as higher product standards and performance parameters are required.

Here in this article, we explain the main criterias that makes top quality commercial vinyl floorings in a manufacturing process. By understanding these criterias, it helps flooring importers to understand how to determine the quality of their products as well as how to find a high quality factory for their commercial grade vinyl floorings.

What is a Commercial Vinyl Floorings?

In a general definition, commercial vinyl floorings are vinyl flooring products that are specifically used for commercial setting. Therefore, a commercial vinyl flooring should have a different product standards compare to residential and domestic vinyl floorings. Two of the main product quality criteria in commercial grade vinyl flooring is in its improving durability and long lasting performance. Some residential householders might choose to apply commercial grade vinyl floorings as it delivers a better quality flooring that makes them feel more comfortable with their products.

Difference between Commercial and Residential Vinyl Floorings

The core difference between commercial grade and residential grade vinyl floorings are generally associated with the thickness of wear layer. As wear layer is the core factor to how much foot traffic a vinyl plank can handle over its product liftimes. However, there are more to the story. In addition to the durability performance, commercial vinyl floorings also offers many features that residential grade vinyl flooring often does not have. These includes safety standards over slipperiness, fire retardant performance, as well as anti-bacterial functions.

| Features | Commercial Vinyl Flooring | Residential Vinyl Flooring |

|---|---|---|

| Wear Layer | Offers thicker wear layer, generally in 0.5mm, 0.55mm or 0.7mm. Some extreme premium grade also offer 1mm thickness. | Residential grade generally has 0.2mm up to 0.3mm thickness wear layer. However, some DIY products also provide 0.1mm wear layer thickness for reduced cost purposes. |

| Fire Retardant | In addition to the fire retardant rating for BFL-S1, commercial vinyl floorings might also request certifications such as IMO product certification for floorings that are applied for special commercial spaces. | PVC compositions are naturally fire retardant, and residential vinyl flooring can meet the BFL-S1 fire retardant rating. |

| Anti-bacterial | For public space applications, anti-bacterial surface is highly recommended. A special anti-bacterial coating solutions are added to provide anti-bacterial effect. | Residential grade vinyl flooring does not generally have an anti-bacterial feature added. |

| Plank Sizes | Depending on commercial project requirements, different plank sizes are requested. From extra large planks that comes with 1.8 meter length, to extra small planks that features 7.6cm x 30.5cm dimensional size. | Common plank size for residential floorings are 22.8cm x 122cm and 22.8cm x 151cm. |

Exploring Commercial Vinyl Flooring Factory in Asia

Where to Explore Commercial Vinyl Flooring Manufacturers

As a flooring wholesaler, access to quality vinyl flooring suppliers are essential for the operation of business and daily sales. A local flooring business generally have access to different local flooring brands and even manufacturers. Leading brands such as Karndean, Polyflor, Mohawk and etc, are some of the leading global brands that offers a wide range of flooring products for local flooring businesses. In addition to local brands, flooring wholesalers can also access to supply chain by importing floorings globally. The most affordable commercial vinyl floorings are from Asia, some of the best marketplace to explore vinyl flooring factories.

| Country | Marketplace Description | Benefits | Disadvantages |

|---|---|---|---|

| China | China has the biggest marketplace for vinyl floorings. With over 1000 suppliers that provide different grade of vinyl flooring products. | High competitive pricings. High concentration of supply chain lead to rapid production delivery. Marketplace is very mature with rapid production lead time and capacity. | Furious competition lead to price competition and some suppliers use low grade materials that diminish product quality. |

| Korea | Korean vinyl flooring manufacturers are known for its reliable quality and excellent reputations. Many manufacturer brands in Korea adapt a local sales strategy, sending their best sales team across different market globally as expatriates. | Korean suppliers such as LX has expatriate sales teams across United States and Europe, allowing them for a more rapid response and services for local flooring businesses. | Price is roughly 35% higher compare to Chinese made vinyl floorings. |

| Taiwan | Taiwanese resilient flooring manufacturers are some of the earliest players in LVT manufacturing. Pioneer product innovations are lead by Taiwanese manufacturers. | Top quality and highly reliable and trustworthy manufacturers. Nothing can go wrong with Taiwanese vinyl flooring manufacturers. | Most Taiwanese manufacturers already work with leading flooring brands. Limited production capacity will lead to longer production lead time for new customers. Price are also higher with Taiwan based factory. |

| Vietnam | Vietnam is the second best market to import SPC products when compared to China. This is especially true if you are an United States business. | Vietnam suppliers offers slightly higher pricing compare to China made flooring products. But with lower tariffs the overall costs of importing from Vietnam can be slightly lower depending on which tier of suppliers you approach. | Production capacity is currently a main issue as there are only less than 20 suppliers in Vietnam. Vietnam also has higher shipping costs, and in time of supply chain disruptions, shipping rate fluctuation can be a major risk for Vietnam based suppliers. |

| Thailand | Thailand is considered the third best marketplace to buy vinyl floorings after China for the similar reasons to Vietnam. Considerable number of Chinese suppliers invested in Thailand to diversify their supply chain risks. | To compare with China and Vietnam, Thailand is considered to have less political uncertainties. While this claim is not precisely valid, many China based manufacturers has also invested in Thailand to diverse the risks in tariffs. Thailand is another sourcing options similar to Vietnam. | Production efficiency is currently the biggest challenges for flooring factories based in Thailand. Lower production yield lead to slower lead time as well as increasing price. |

| India | Unlike Vietnam and Thailand, the India resilient flooring manufacturers are mostly local invested. With closer distance with European markets, India vinyl flooring products has well expanded across Europe. | India made vinyl flooring has closer distance to European markets. Shorter delivery time and freight costs. | Innovations in products with India based manufacturers are limited due to less concentrated industry clusters. |

Considerations by Major Flooring Brands

As a strategy for diversified global supply chain risks, flooring brands are currently buying their products across China, Vietnam, and Thailand over their entry price flooring collections. However, as part of the supplier partnership request by the brands, many Chinese leading suppliers (that works with leading brands), has also invested their premium product production lines in Vietnam and Thailand. As more production lines are invested and built by the suppliers, production capacity will gradually be made available for new and smaller clients. However with much political uncertainties with US-China relations, investing in production expansion also has its risks. Therefore the market is expecting a shift of global supply chain, but with slightly less haste and confidence.

With exception to Asia based suppliers, new investments (for resilient flooring industry) are also hold with other countries such as Dominican, Egypt, Nigeria, and Mexico. This is also due to the global anti-China sentiments which many predicted at sometimes in future, there might be a economy and trade breakage even between China and Europe. While this perspective has yet to have a strong indicator to support its prediction, many industry investment panels and actions are already taken hold for investment for factories on other parts of the world.

How to Determine the Quality of Vinyl Flooring Factories?

Here are som indicators for determining the quality of vinyl flooring factories:

| Indicators | Description | Indicator |

|---|---|---|

| Manufacturing Capabilities | Manufacturing capabilities suggests that the suppliers has the ability to produce different type and grades of flooring products. This may include standard product lines of LVT and SPC, or commercial grade LVT and SPC, or other innovative resilient flooring product lines. | A specialised vinyl flooring manufacturer generally has different level of manufacturing capabilities. Some capabilities are more unique while others might be very generic that all vinyl flooring factories must have. |

| Experience in Markets & Customers | Different market has different product standards and requirements. The more global clients the factory has supported, the easier and more reliable the factory will be when trading with them. | Experience with major brands is a strong indicator for quality, price, and manufacturing capabilities. However if no experience was with the major brands, then clients from your own local markets are also good. The last is working with international clients at either Europe or United States markets. |

| Use of Quality Raw Materials | Luxury vinyl floorings (LVT/SPC) are made from compositions of PVC polymer, calcium carbonate, and plasticisers. Using quality raw material compositions is essential to product quality vinyl floorings that is both durable and no toxic. | There is no good visual indictors for consumers to determine the toxicity of their vinyl floorings. Even with major brands that sourcing their flooring from Asia, from time to time, will find material toxic issue due to manufacturers trying to cost down. It is therefore important for irregular factory auditing to review suppliers’ material sourcing documents and onsite materials storage an use conditions. |

| Manufacturing Capacity | Different manufacturers has different manufacturing capacity. The capacity is reliant on the number of production lines available in the factory. Its worth noting different vinyl flooring products actually need different production equipment (the manufacturing capability). | To categorise different size of factory, the general rule of thumb goes like this: Workshop Factory: Less than 10 extrusion lines for SPC. Medium Size Factory: 10 to 20 extrusion lines for SPC. Large Factory: More than 20 extrusion lines for SPC. |

How to Work with Top Quality Commercial Vinyl Flooring Factories

Working with top quality commercial vinyl flooring factories are ideal if you are preparing to launch vinyl products that are targeted towards more premium flooring markets. However, with overwhelming information and false information in the market (whether from exhibition shows, B2B platforms, or search engine), the risk of finding a not so qualified suppliers are significant.

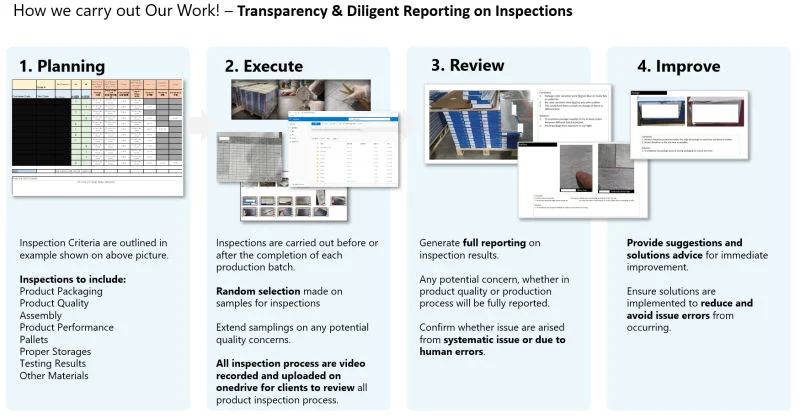

As much as getting the best prices from different resilient flooring manufacturers, getting a reliable and integrity supplier is more essential for international trading and importing. This is where Sreelance material technology, as a professional sourcing company can help. By working with Sreelance, your product sourcing from Asia is fully monitored and reported. Product inspection process is transparent and uploaded for you to view anytime.

You can reach out to our team via sales@sreelance.com , or contact us through the form below:

Latest Featured Vinyl Flooring Product Solutions from Sreelance

- Polypropylene Resilient Flooring

- Self-Regulating Floor Heating System for Resilient Flooring

- Smallest Herringbone Click SPC / LVT in Industry

- Laminate Like Scratch Resistance Vinyl Flooring Planks

- A/B/C/D Low Repetition Pattern Designs in Vinyl Flooring

- Hybrid ABA Structure Vinyl Flooring

- Hybrid Acoustic Luxury Vinyl Flooring

- Hybrid Wood Veneer Rigid Core SPC (V-SPC)