When it comes to luxury vinyl flooring, there are hundreds and hundreds of products and collections to select from. The resilient vinyl flooring industry has built a supply chain industry cluster that can effective provide any styles and designs in vinyl flooring products. The customization can go from pattern design & colors and material product specifications. Whether its semi-rigid LVT or rigid core SPC planks, leading manufacturers are on a continuous raise to roll out new products, some are more innovative while some are not too innovative. However, as vinyl flooring markets has reached an increasing high capacity and maturity, vinyl flooring products are becoming more homogeneous and indifferent. Innovations under the PVC composition remains very limited, and price competition is driving down profit margin for both manufacturers and flooring distributors.

To this extend, this article focus on the best of best vinyl flooring products that are being launched for 2026. As 2026 is a turning point for global supply chains, especial for thus focusing on the United States markets.

Innovations through Investments

Currently in China you can already explore a wide range of vinyl flooring products from many professional vinyl flooring manufacturers. However, most of the on market products are ordinary grade and has very few unique selling points as it can be easily manufactured by other suppliers and factories. Product innovations in luxury vinyl floorings can occur in two directions in essence. One focus on exclusive pattern designs and development for unique designs, color collections and surface texture. The other focus on the combination of materials and specifications. These two innovation directions supports the manufacturers to provide more unique and newer products that other suppliers does not have. All of these innovations requires investments, and the more are being invested, the more unique product propositions a vinyl flooring manufacturer can provide.

Product Innovation Directions Briefly Explained

Innovation Through Pattern Designs

Consumers and interior designers are constantly looking for new design elements and styles to work with different project demands. This is something that leading flooring brands are committed at, offering a wide range of exclusive pattern designs with comprehensive color choices to capture the markets. However, the investments are mostly depleted by the suppliers as major brands has significant purchasing power that made manufacturers willing to invest to maintain the business with these major brands.

Pattern design investment costs are associated with development for new designs, the printing gravure cylinders, development costs in new color adjustments, and embossing in register plates or cylinders. There are also investments for digital printing technologies. Digital printed vinyl flooring offers less repeated pattern design, and are able to make more unique designs with minimum quantity orders.

- Original printing designs for Vinyl Floorings

- 4 sets of gravure cylinders for high definition printing

- Development costs for color adjustments

- Embossing in register plates and cylinders

- Digital Printing Production Lines

Each of these investments allows the manufacturer to provide more unique design products in their vinyl flooring collections. Some exclusive designs are highly popular in the market, and the flooring brands can benefit from having these exclusive products. This exclusivity is often tied up with manufacturers (either decor film factory or vinyl flooring factory) that invested in developing these exclusive patterns.

Innovation Through Material Design and Specifications

Different flooring manufacturers has different production capabilities. Some put more investments in the latest and unique production equipment, some put more focus on new material developments and works on existing production facilities. Each of these product innovation provide different competitive edge, so for flooring importers different product demands might be fulfilled across different suppliers instead of just one.

Examples of Innovation Through Production Equipment Investments

- Extra Large Hydraulic Thermo Pressure Line: The best of extra large LVT flooring are made using hydraulic thermo pressure line. Standard hydraulic thermo pressure line can only make 1.2 metre length LVT planks and extra large hydraulic thermo pressure line allows up to 1.8 metre length LVT. The capability to produce extra large LVT planks also requires better controlling in production process and material composition formulas for improving physical properties.

- Specialized Slotting for Extra Small Dimensions: Extra Small click LVT and extra small click SPC that has a width of 7.6cm is hard to come by, as it requires a specialized slotting line for small width slotting. Standard slotting line can make width above 100mm while this specialised slotting can make planks below 100mm. However, this slotting line has very limited production capacity, and only the best of manufacturers that service for major brands provide this product options.

- Cold Press Pressure Line: Th cold press line is a highly flexible production process as it allows different materials to be laminated together. This includes WPC floorings as well as V-SPC and other hybrid flooring that applies different materials together.

Example of Innovation Through Material Compositions

- Non-PVC Flooring: Using alternative polymers during the making of LVT or SPC floorings. These alternative polymers such as PET or PP plastics requires slight adjustments on the extrusion production line. However, the formula for the PET or PP composition is highly essential to the performance and quality of the flooring.

- Coating Composition Technology: Different coating formulas allows for different functionality to be achieved through surface coating. Some might include anti-slippery, anti-bacterial, and additional surface anti-abrasion performance. These high performance coating technology can effectively improve the resilient flooring product performance and outstand in the flooring market.

- Underlayment: Underlayer of resilient flooring planks might not been seen as such a huge deal in flooring innovation, but are still an important element to the flooring products. Different underlayments provide different acoustic and anti-slippery performance. Unique products such as loose lay grip LVT helps to realise thin LVT tiles to be loose lay installed. Other materials such as magnetic underlayer also supports new and innovative ways for flooring to be installed. IOT technology are also associated with self-regulated heat underlayer which provide an energy efficient floor heating system for householders.

- Low Density Core Vinyl Plank: Conventional rigid core SPC flooring has a density that is above 2.0g/cm3. However, with recent composition technology, a light density rigid core is being invented. The density for light core L-SPC is roughly around 1.6g/cm3, a 20% reduction in weight. This precision control over the foaming of SPC core during the extrusion process requires a strong manufacturing controlling. The L-SPC is considered the next vinyl plank product that could possibly replace WPC.

What’s Hot for 2026 Resilient Flooring Trends

Trends in Flooring Pattern Design

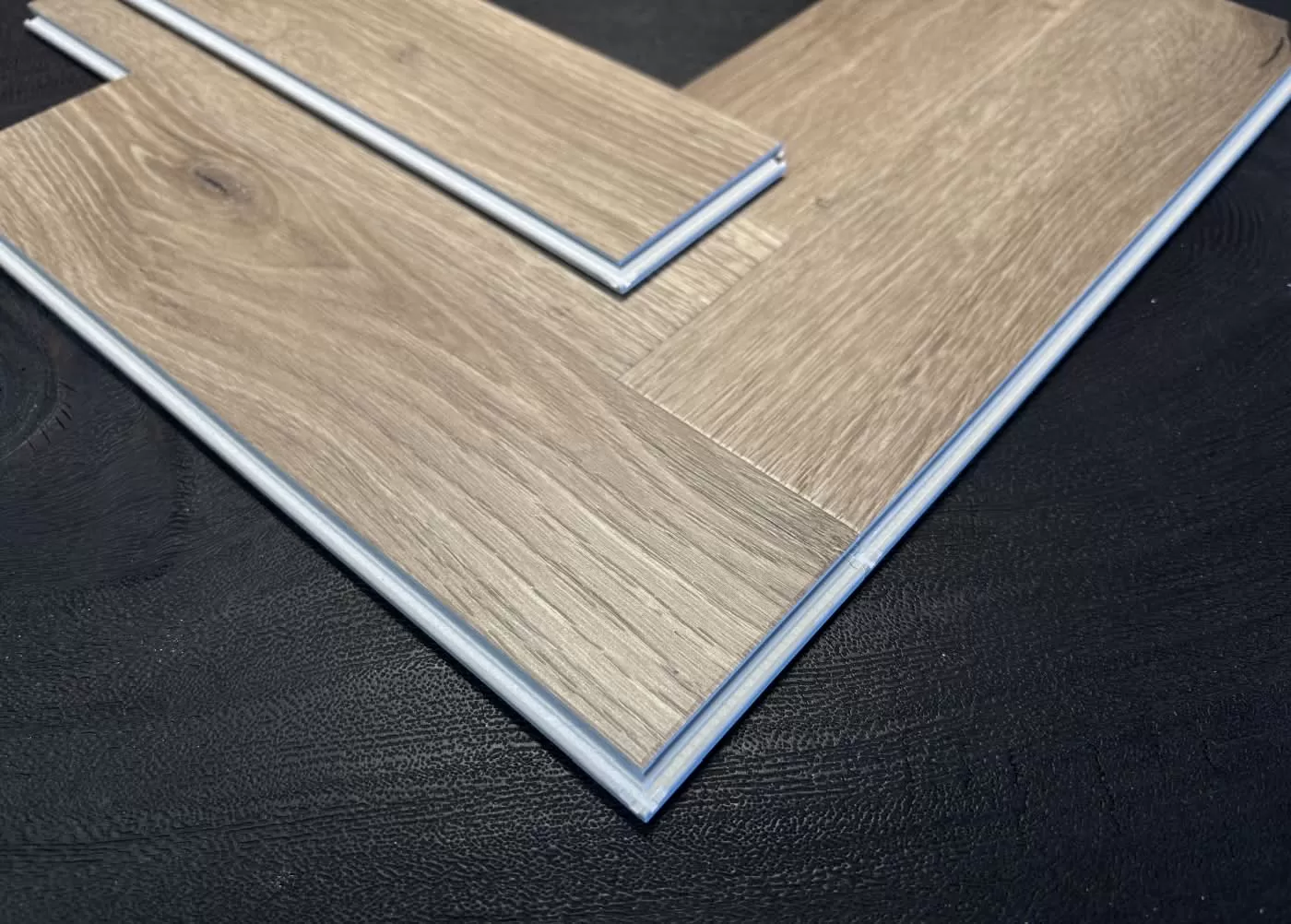

The global flooring market has undergone some interesting change in design and color preference over the past few years. Pattern design change has went from more complex and featured elements to more simple and minimalistic styles. Soft and natural colors has a strong comeback and this has to do with interior designs trending towards to new niche for better healthy lifestyles that narrate natural materials and simplicity. Natural woods without complex features are currently a major style that are prefered by interior designers. Color selections such as beige and nature light colors are extremely popular in 2025, and this color trend will likely to continue into the 2026 year.

Trends in Resilient Vinyl Flooring Products

With increasing product competitions within the resilient vinyl flooring category, new resilient flooring products are being developed and launched into the market. Some of these new flooring products are more popular and unique than others, and flooring brands are focusing on new product launch with these new resilient vinyl flooring products;

- Thicker Rigid Core SPC and WPC Flooring

- Extra Large Vinyl Plank Floorings with ABC pattern designs for less repetitions

- Extra Minisize Herringbone Click Vinyl Floorings

- Herringbone Click SPC with Unizip (Unilin) Click & Lock Design

- Light Density L-SPC Floorings

- Self-Adhesive 2.0mm Luxury Vinyl Tiles

Thicker Rigid Core SPC and WPC Flooring

As one of the most popular flooring category, SPC flooring has surged as one of top selling product in floorings. With increasing sales demands, major flooring brands are launching thicker rigid core SPC flooring collections to cater more premium grade of flooring collections. 6mm SPC has been a top selling product, however to deal with slowing growth momentum in 6mm SPC, 8mm rigid core SPC flooring and 10mm WPC floorings are being launched.

Extra Large Vinyl Plank Flooring with ABC pattern designs

Bigger planks provide a more robust flooring styles for interior design. However, conventional vinyl flooring products does not generally provide large plank length above 1.8 metre long. This is partially due to both the cost of developing for extra long pattern designs as well as insufficient physical properties for larger planks. In other words, many resilient vinyl flooring manufacturers does not have enough capability and know how to achieve the level of quality that are required in extra large vinyl planks. In addition, longer planks requires more gravel printing cylinders to be developed so that pattern repetition can be reduced. With 22.8cm width, a set of gravel printing cylinders can produce 4 individual plank patterns, and two sets can produce 8 individual planks. For flooring brands or flooring distributors that are launching extra long planks with 1.8 metre length, 2 or 3 sets of gravel printing cylinders are more ideal.

Extra Minisize Herringbone Click Vinyl Floorings

Small size herringbone click vinyl floorings are becoming more popular in Northern Europe markets. The need to mimic the herringbone parquet with the element of classic renaissance theme requires vinyl plank tiles to have narrow plank sizes. The extra small planks with only 7.6cm width, plus the requirement for slotting the click system, requires a specialized line that has very limited production capacity. It is therefore only available with the best of best vinyl flooring factories even in China. The extra minisize herringbone click vinyl flooring generall has a width to length ratio of 1:4 or 1:5. But smaller ratio of 1:3 is also available by brands such as Karndean. Different size of XS herringbone LVT and SPC are available below;

- 7.6cm x 22.8cm

- 7.6cm x 30.4cm

- 7.6cm x 38.0cm

- 7.6cm x 45.6cm

Herringbone Click SPC with Unizip (Unilin) Click & Lock Design

Conventional herringbone click SPC can be a bit daunting to install and requires a A+B planks to jointly interlock and pave. With newer click & lock technology, the latest click design that is launched by Unilin allows the planks to be installed regardless of which planks are used. This unified design makes installation simpler and allows the planks to be more randomly paved when installing. Unizip locking system is available for standard herringbone plank sizes that has a minimum width of 10cm.

Light Density L-SPC Floorings

The invention for light density L-SPC flooring has two main purpose. One is to provide an alternative vinyl flooring options to WPC flooring products. The other core reason is to achieve a continuous production process in vinyl plank extrusions. The original WPC flooring requires a two step production process, while with L-SPC productions it only need one production line process. This significantly reduce the time and labour requirements while diminishing the need for cold press production process.

Self-Adhesive 2.0mm Luxury Vinyl Tiles

Self-adhesive luxury vinyl tiles is a popular flooring product among smaller DIY projects and temporary floor covering tasks. The self-adhesive underlay need very minimal work and can be instantly installed without applying glue. However, it is generally made from lower grade composition with very thin wear layer protections. Self-adhesive LVT can be easily find on e-commerce platform as well as in big box building material stores.

Best of Best Vinyl Flooring Products in China

Considering about the best innovations and investments in new vinyl flooring products, the marketing team of Sreelance considers some resilient flooring products are more technical demanding and more advanced than others. The best of best vinyl flooring products for 2026 considers the uniqueness and higher product standards that is required in the manufacturing. Hence the best of best vinyl flooring products are in following;

- Chevron Click LVT and SPC Flooring

- 1.8 metre length Extra Large Click LVT and SPC Flooring

- Extra Minisize XS Herringbone Click LVT and SPC Flooring

- Light Density L-SPC Flooring

Chevron Click LVT and SPC Flooring

When it comes to dimensional stability requirement, there is no higher demand in in vinyl flooring than chevron click LVT. The 45 degree angle plank point requires higher dimensional stability rate of under 0.001% to maintain in shape and not buckle after their are installed. Any vinyl flooring manufacturer that can produce this style of vinyl flooring products has the highest level of production management controlling and formulated materials. Chevron click LVT has the highest vinyl flooring product standards compare to any other type of vinyl plank floorings.

1.8 metre length Extra Large Click LVT

Semi-rigid click LVT with extra large planks often has curling problems, a phenomenon where Chinese manufacturers call them “Banana Curl”. With semi-rigid base layer, higher dimensional stability are also required with extra large and long length LVT planks. Though, the stagger pavement style is more stable so it’s minimal quality requirement is slightly lessen compare to chevron click vinyl floorings.

Extra Minisize XS Herringbone Click LVT and SPC Flooring

Extra small and minisize herringbone click LVT and SPC are hard to comeby due to the requirement for the specialised slotting machine. Many vinyl flooring manufacturers has not invest in this production line due to the cost of the machine. It is said to need about 1.5 million USD to establish this production line, and even with client’s demand, manufacturers hesitate to make investment due to very small production scale with this slotting line.

Light Density L-SPC Flooring

Light Density L-SPC core applies a foaming technique during the extrusion process. As the L-SPC core needs to have a consistency foaming rate across the extrusion process, precision controlling and formulating is essential. A better production controlling process allows for thinner L-SPC of 6.0mm core to be provided, while the more common (and less precision controlling) provide L-SPC core above 8.0mm. Note that the higher precision controlling does not contribute to neither production scale nor lower cost structures, so even for major vinyl flooring exporters that supply for major leading brands has strong incentives to provide more precision controlled vinyl flooring product collections.

Short Conclusion

The best of best vinyl flooring products mentioned in this article is based on the point of level of technologies associated in manufacturing these products. Market preference and popularity also considers about retailing prices as well as brand impacts. Not all innovative flooring products will success in the flooring markets, and flooring brands as well as flooring distributors also needs to consider other factors that lead to successful sales and customer satisfaction.