Last week on Friday marks the end for the 3-day exhibition for the 2023 Domotex Asia / ChinaFloor Trade fair. As most of the industry players should now, it is considered the biggest flooring expo that is hosted across Asia and also the 2nd largest one globally. This year’s Domotex Trade show is the first trade show that is freely accessible to foreigners since the 2020 Pandemic, and we have observed there are significantly more foreigners and global participants coming to this event. As such, suppliers and manufacturers across Asia has come together to participate the event where many of the latest product innovations and designs are being displayed. During the event, various seminars were hosted where flooring and interior design exports delivers keynote speech to discuss the recent factors that is currently affecting the architecture & interior design markets.

In this article, we cover a summary of observations regarding the topics being discussed in the seminars as well as product innovations in resilient floorings (mainly LVT and SPC categories).

Major Discussions at 2023 Domotex Asia ChinaFloor

During the three days event, more than 30 seminars were hosted with speakers coming from architecture firms, interior designers, major brands, manufacturers, consultants, academics and relevant industry associations. Major topics were being carried out in topics of Cross-border communication across industry supply chain, interior design applications, material engineering, building industrialization and smart home living.

Its worth noting that during the keynote speeches, there has been constant mentioning about multi-dimensional / multi-functional spatial design, where consumers are exploring interior designs that offers multifunctional purpose in a highly urbanized setting. Quality living with green decorative products are also a major topic that has been brought up where the industry are initiating for low carbon emission and carbon neutrality in production of various of building materials. Lastly, as consumers behaviors are in constant changing, there is a need for more convenient and rapid remodeling in interiors.

Mega Trends in Resilient Floorings

What the Major Vinyl Flooring Suppliers are doing?

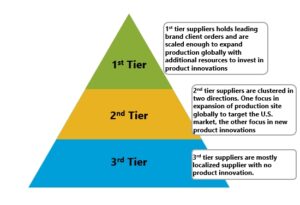

During the visit at the 2023 Domotex expo, we have observed that suppliers of resilient vinyl floorings falls into two direction of strategies. One is focused in the expansion of supply chain and factory sites in locations such as Vietnam and Mexico, and the other focus in development of new products in resilient floorings. Interesting enough, the two strategies are generally not carried out simultaneously by suppliers, only the highly ranked supplier which ships over one thousand of containers monthly has expanded their factory sites internationally while engaging in new product developments. As such, we have observed that Chinese suppliers that expand their production site internationally are only offering standard flooring product lines in LVT and SPC. In this exhibition, we have observed suppliers from Korea, Vietnam also only offers standard LVT and SPC.

Trend for Vinyl-Free Flooring Development?

Viny-Free Floorings continue to be one of the most important product development trend in the industry. Not only we see first tier suppliers rolling out their vinyl free LVT and vinyl free SPC, we also were informed exclusive sales rights were demanded from leading flooring brand. This is an indication that it is in brands’ interest to eventually phase out PVC-based floorings, and they are strategically capturing exclusive suppliers in this line.

Vinyl-Free Floorings are currently being developed in two directions, one is PET polymer based, and the other Polypropylene (PP) based. There is no certainty which one will lead as we have observed different major brands has chosen different material (as well as relevant suppliers / developers as they are closely associated).

Vinyl Free LVT/SPC will be the mega trend, according to expert at 2023 Domotex Asia Trade Show: “More than half of the flooring brands that participated the Cologne Expo in Germany has displayed non-pvc floorings instead of the normal PVC based floorings”.

New Resilient Flooring Products showcased at 2023 Domotex Asia

In addition to the vinyl-free trend, there has also been new product development where different focus was implemented. The most interesting products would be the carbon core vinyl floorings that has a specialized function to absorb formaldehyde. Other innovations has focus in lower density in SPC (which was a major concern during the pandemic time), and improved fire resistance performance for application settings such as cruise ships. Lastly, there are mineral based SPC with wood veneer top layer.

Added Comment: Vinyl Free LVT/SPC will be the mega trend for the flooring industry, according to industry expert from the show, more than half of the flooring brands that participated the Cologne Expo in Germany has displayed vinyl-free floorings as their featured products. Conventional PVC based vinyl floorings are losing its spotlight in Europe.

Below we display some of the innovative resilient flooring products that was showcased by different manufacturers at the 2023 Domotex Asia Flooring trade fair.

Rigid Core PP Flooring

As the name suggest, this vinyl free LVT does not contain any PVC. From the very top layer to print film and base layer are all made of Polypropylene (PP) polymers. PP polymers are a more environmentally friendly material as it does not contain any toxic substance. In addition, it use less energy in production, having less carbon footprint and are more easily recyclable. It also has a higher dimensional stability as PP polymers has higher melting point than PVC.

| Advantage of PP Floorings | Disadvantage of PP Floorings |

|---|---|

| 1. Superior Dimensional Stability 2. No contain of chloride nor dioxin 3. During flaming, it produce white smoke instead of black smoke ( a physical observation for less toxic fume ) 4. Are easily recyclable by physical method | 1. Polypropylene naturally are more flammable. It needed anti-flame additive to improve its fire rating. (hence higher cost associated with). 2. PP flooring yellowing is also a concern noted by PET flooring developers. 3. Cost of PP-SPC is about 50% higher compared to standard SPC |

CARBON CORE SPC FLOORING

Bamboo carbon composite are used in the making of Carbon core SPC. It is a light weighted SPC with the property to absorb formaldehyde. In addition, it also release negative oxygen ion which further improves the air quality in the space. However, as it is light weight (lower density) with less rigidity, it has a minimum quickness of 6.7mm. The locking groove has also been observed to be more easily fracture compared to standard SPC planks. The cost of Carbon Core Flooring are 2 times higher than standard SPC with similar specifications.

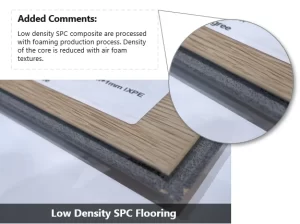

Low Density SPC Flooring

Low density SPC or Light SPC planks are manufactured with foaming techniques in the base core of SPC. The foaming process allows the rigid core to obtain lower density with reduction in raw material use. The density can go as low as 1.2 kg/m³ where standard PVC SPC plank has 2.6 kg/m³. The cost of Low Density SPC is almost equivalent to standard SPC.

Added Comments: Low density SPC composite are processed with foaming production process. Density of the core is reduced with air foaming textures. A very similar production process that is used for making WPC.

Luxury Marine Tiles with Compliance to IMO

Luxury Marine Tiles is an upgrade to the existing PVC based Luxury Vinyl Tiles. With the material composite being modified to deliver improved performance in fire resistance and smoke density. As it is specifically designed to use in cruise ships, the flooring have to comply with standards set out by the International Maritime Organization. The cost of Luxury Marine Tiles is about 2.5 times the cost of standard SPC material.

Veneer SPC Flooring

The Venner SPC flooring is an advanced SPC that applied both wood veneer and magnesium composite materials. With the top layer veneer, this SPC has the appearance of real hardwoods while being fire-proof and water-proof. The price range for veneer SPC flooring is dependent on the wood species and veneer thickness.

Development Challenges in Polypropylene based LVT and SPC

As there are now many suppliers working in the development for PP-based floorings, a common challenges the industry has faced is the bonding and adhesive issue between layers in PP flooring. In conventional PVC flooring, the PVC material can be easily bonded together with oil-based ink. However, the covalent bond between PP polymer with water-based PU ink is different making the bonding ineffective during the heat curing process. In short, PP film does not bond well with PU ink in between.

A common solution to this (which we have observed from on market products) is to apply glue like (PUR) coatings which can effectively bond the layers together. However, this practice in our opinion is not the ideal solution as it adds cost and has other potential concern in applied adhesives. Our solution focus in developing a modified PP print film that can effectively bond together in low temperature manufacturing processing without the need for PUR coating.

Solution Provider for Polypropylene LVT / SPC Manufacturing

Here at Sreelance Material Technology, we are deeply involved with upstream supply chains. This means we offer more than just a finished product. We support brands and even manufacturer of resilient flooring to select materials from composite compounds to printing films, pattern designs and whole flooring planks.

Currently we have initiated developments in high scratch resistant PVC wear layer, and Polypropylene (PP) based LVT/SPC formula. Manufactures of LVT & SPC can source our semi-finished materials to implement into their production lines.

We have worked on solutions in developing materials for PP-LVT/SPC with the consideration of existing production facilities that is currently producing standard LVT/SPC product lines. We provide raw materials in the form of PP-Print Films, PP Wear layer with Print Film, and modified composite for extrusion of base material for PP floorings. Our material solution is meant to support existing vinyl flooring manufacturers to effective switch their product line without major adjustment to their current equipment or investments.